20mm Dia Screw Kit DIY Desktop Extruder Injection Parts Nitrided Drilled Barrel Nozzle Heaters Temperature Controller

In the Package:

-

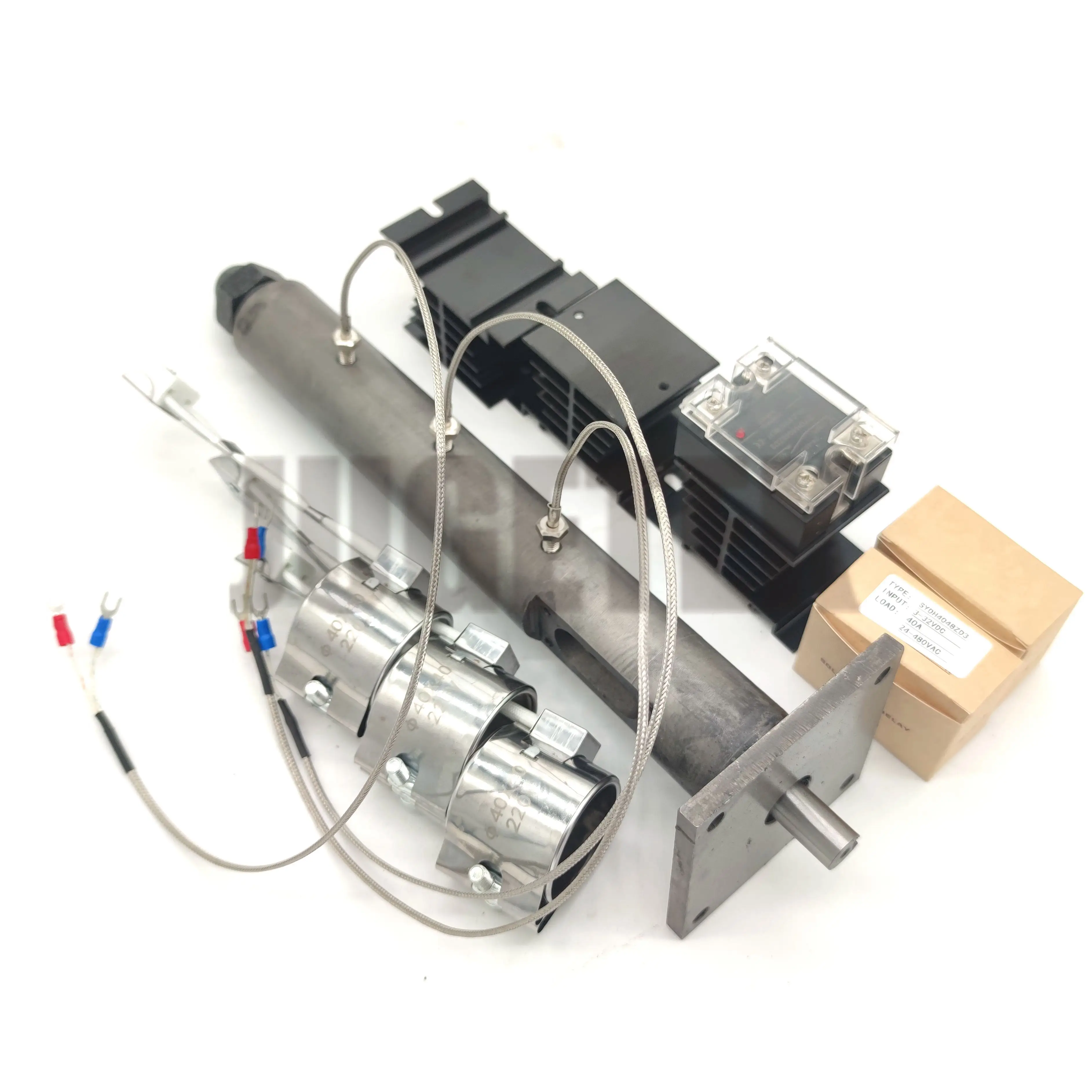

1 set 20mm screw Kit (barrel, screw and nozzle)

-

3x 4040-150W Band Heaters (220V, up to 175

-

OR 4040-230W Brass Heaters(220V up to 350℃

-

3x SSR40A Solid-State Relay

-

3x KTC-05M6 Thermocouples 0.5meter M6 thread

-

3x HSSSR-B Heatsink for SSR Solid-state Relay

-

3x REX-C100 Temperature Controller REX-C100

-

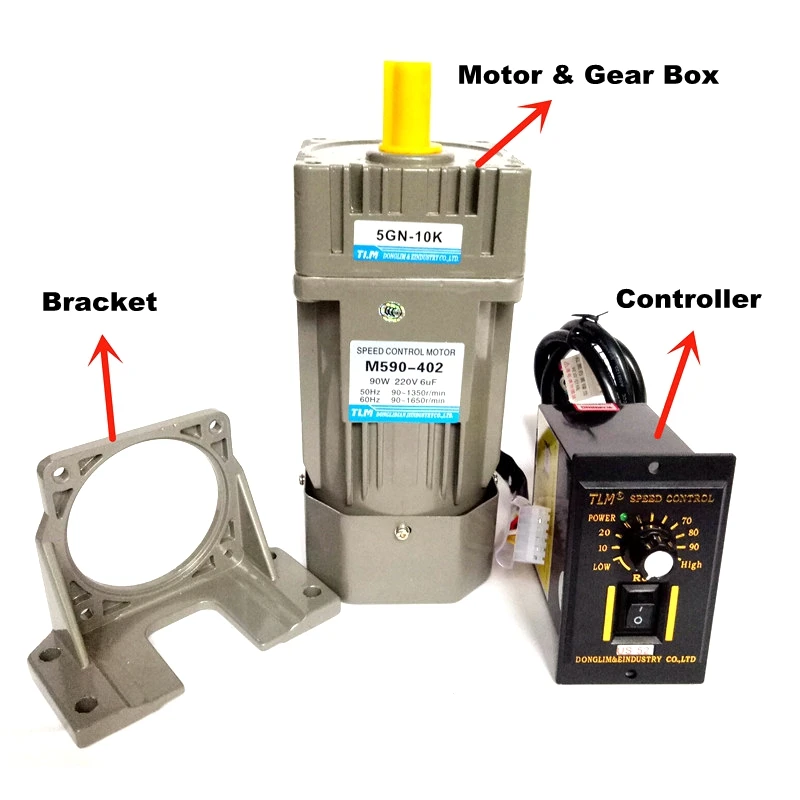

1x 110/220V 90W Induction motor with Gearbox, US-52 controller and Bracket. Reduction ratio from 3:1 to 180:1

-

1x Clamping Rigid Coupling for connection between screw and shaft of gearbox, 14mm-15mm ID

Specifications:

Productivity: 0.1~0.5kg/h, 20g per shot

Suit for HDPE, LDPE, LLDPE, PVC, PP, glass fiber, PPS, PPA and other special plastic recycling.

Maximum rotation speed: 60RPM

Maximum heating temperature: 450℃

Bimetallic layer depth: 3 mm

Bimetallic hardness: 57~69HRC

Hard-chrome plating hardness after nitriding: ≥950HV

Chrome-plating layer depth: 0.03-0.09mm

Surface roughness: Ra 0.4

Compression Ratios: 20mm extrusion screw is 2.8

Technical Information:

Main Base materials

1.38CrMoAlA (SACM645)

2.SKD-61 (Special Tool Steel)

3.42CrMo (Ultrahigh Strength Steel)

4.DC53 (Cold Work Die Steel)

5.W6Mo5Cr4V2 (High-Speed Tool Steel)

Processing Techniques

1. Heat treatment

2. Quenching

3. Bimetallic alloy welding for screw

4. Bimetallic alloy centrifugal casting for barrel

5. Hard-chrome electroplating

6. Linearity of screw:0.015mm

Drawing:

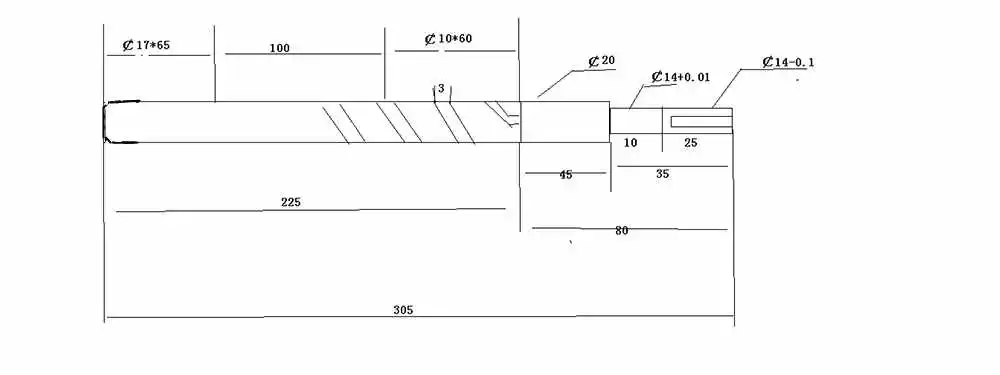

Screw:

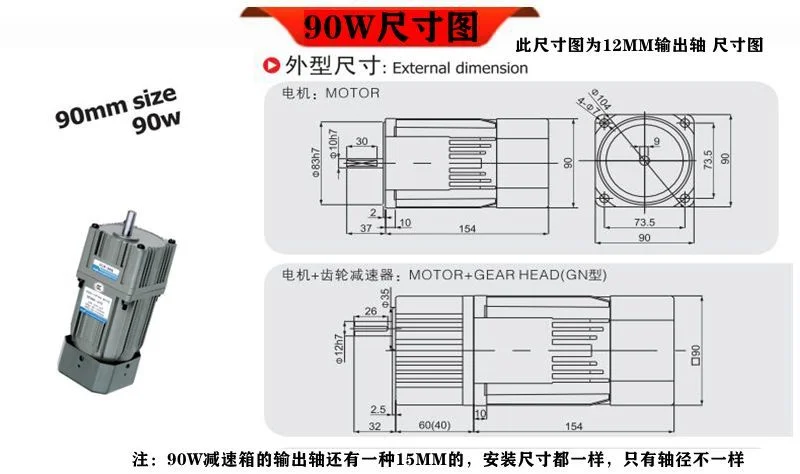

Barrel:

Specification of Motor: